Low-melting metals like bismuth are used as lost molding cores in the refractory industry, because of their beneficial mechanical properties. Here we present a new solution to replace bismuth with a more sustainable and cheaper solution.

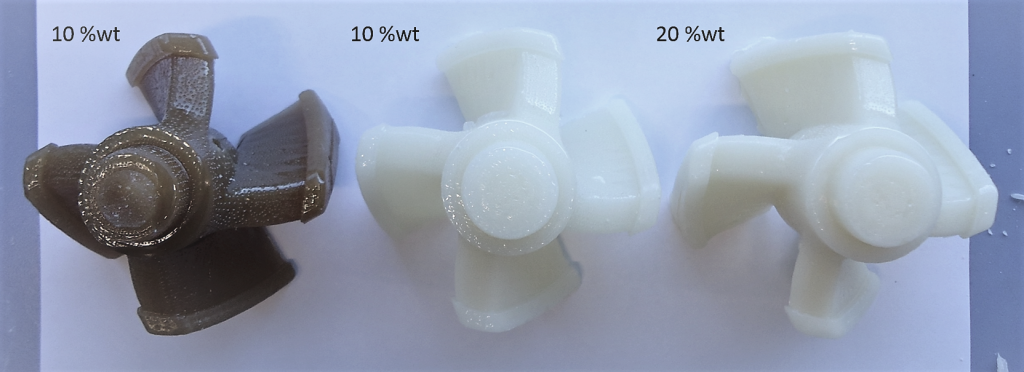

Low-melting metals like bismuth are used as lost molding cores in the refractory industry, because of their beneficial mechanical properties. Besides the high costs and heavy weight, these metals are difficult to recycle and critical in terms of toxicology and disposal. Together with proionic´s partner RHI Magnesita a new solution was developed to replace bismuth with a more sustainable and cheaper solution (for details see WO2020127980 “Mold Composition Comprising a Sugar Component“). The final lost core material utilizes sugars as base components, in combination with carefully selected fillers; at an optimized formulation the characteristics of the new solution are superior compared to conventional mold materials like bismuth. The inexpensive, non-toxic, and lightweight sugar solution shows better results in terms of hardness and recyclability. Compared to other possible lost core materials such as various waxes or thermoplastics, the sugar-based lost cores are mechanically superior and are easier to remove, due to the significantly better rheology and freedom from residue in the melting-out process; this makes them more suitable for sophisticated and complex lost core structures and cavities.

Roland Kalb, Executive Director R&D & Founder:

“We started investigating frozen ionic liquids as lost core materials and had some issues with hardness and hygroscopicity. Since our eyes and minds are always open for the best solution, we ended up with a sugar-based solution. The developed material could be a game-changer and is applicable in many industries, including the refractory industry!”