Research and Development

We are excited to develop revolutionary innovations with you. Do not just look for improvements – strive for real leaps in innovation!

Profit from 20+ years of experience

As a pioneer in the field proionic has extensive experience in the development, production and application of Ionic Liquids.

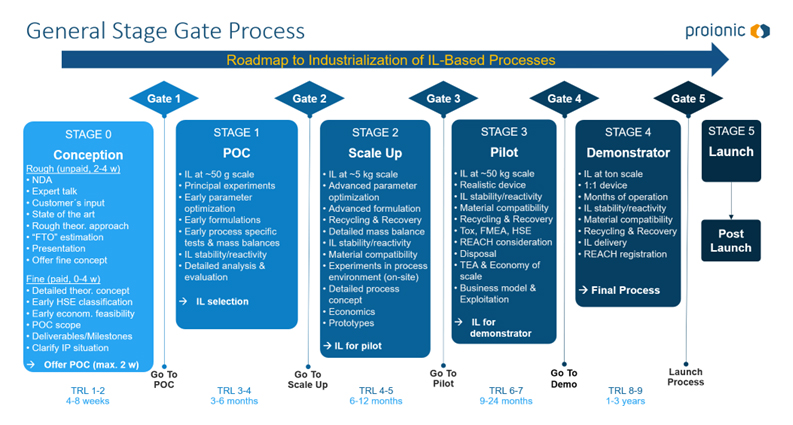

From a theoretical concept to pilot and demonstration scale

Research & Development specials

01

20+ years of experience

proionic has accumulated the know-how and experience regarding Ionic Liquids, its applications and the development of Ionic Liquid-based processes. Having involvement in many different industries proionic is fast in understanding customers’ needs and chemistries.

02

Quick screening of candidates

The CBILS® process allows screening of many different Ionic Liquids in a short period of time. This helps to check the previously generated theoretical concepts on lab-scale. Besides new structures that can be synthesized hundreds of Ionic Liquids of different classes are available on stock for proof-of-concept studies.

03

Database of key parameters

proionic owns a large database of important physico-chemical parameters of Ionic Liquids and all relevant equipment to determine the most important parameters for new candidates.

04

Engineering know-how and scale-up experience

Due to the engineering background of proionic and the robust production process new Ionic Liquid candidates can easily scaled up from gram to ton scale. Different equipment sizes covering this range are available.

Key benefits of Ionic Liquids for your process

01

longer lifetime

Due to their high stability Ionic Liquids have a longer lifetime than other operating fluids.

02

safer processes

Processes based on Ionic Liquids are typically safer and cleaner as they do not contaminate the gas-phase and are non-flammable.

03

sustainability

In many processes Ionic Liquids can be recycled and reused, preventing waste and pollution.

04

performance booster

Ionic Liquids potentially boost the performance of standard products, even when applied in small concentrations.

05

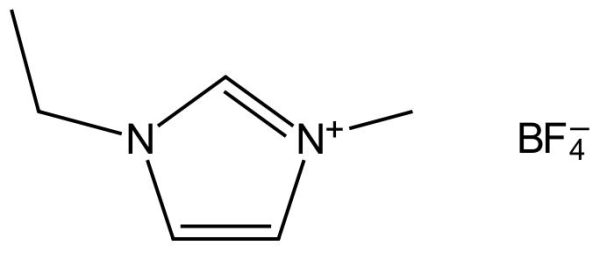

structural variety

Many different functional groups can be incorporated into the cation or the anion which allows flexible design of Ionic Liquids specifically adjusted to the demands of the application.

06

continued innovation

Since Ionic Liquids are a relatively new material class with exceptional characteristics, there is still room for further innovation, new findings and related new IP/IPR.

Main applications

01

Electrolytes

for batteries, supercaps, sensors & advanced materials, pure or part of a mixture

02

Solvents

for natural and syntetic polymers, safe, environmetally friendly and recyclable

03

Operating fluids

like lubricants, hydraulic fluids, coolants, etc

04

Antistatic agents

for polar matrices

Proionic Ionic Liquids

Unmatched technologies for a more efficient, green and safe technical synthesis of ionic liquids.

Technological features - CBILS®

- Exclusive production technology

- Efficient production of ultra-pure ionic liquids

- Safe, halide- and waste-free production

- Scalable and ecological production processes

- Low water levels on small and large scale

- High batch-to-batch stability

- REACH registrations available

Services

- Targeted development of application-optimized ionic liquids

- Development of new applications

- Process and process-engineering based expertise for targeted implementation of client requests

- Applied design of ionic liquids

- Tailor-made solutions according to your specifications

- All ranges from kg- to ton scale

- Bestseller ionic liquids in stock

- small test quantities are available through Carl Roth