Cellulose Reshaping

Ionic Liquids release nature’s abundant supply of building blocks, gently dissolving them without alternating the primary structure of the original molecules. New bio-based materials can be formed. proionic’s experience includes not only cellulose, but also other biopolymers like hemicellulose, lignin, chitin, chitosan.

A sustainable source of bio-based materials

Shape the Future!

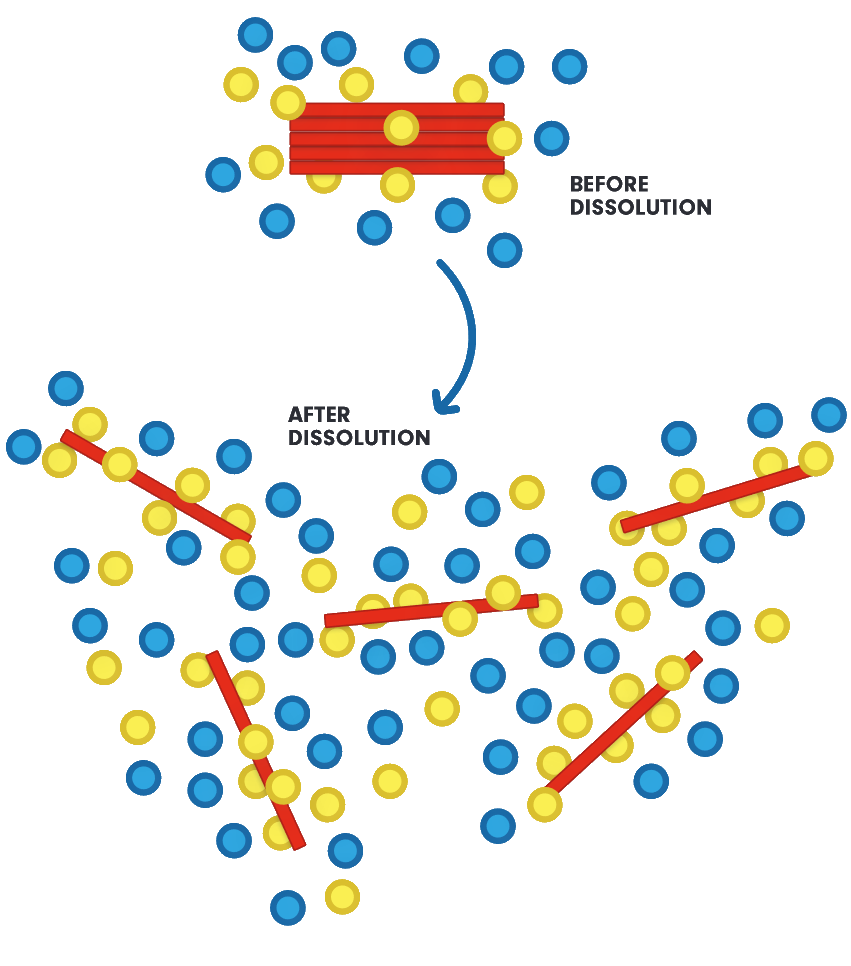

Ionic Liquids gently dissolve cellulose

Ionic Liquids are suitable for a wide range of bio-based polymers

Ionic Liquids only split hydrogen bonds in biopolymers but do not affect or deconstruct the biopolymers’ primary structure, which leads to a mild and gentle dissolution. No further chemicals or additives need to be added during processing.

This mechanism works for various types of raw materials. Cellulosic or lingo-cellulosic feedstocks, including agricultural and forestry waste, switchgrass, sorghum, poplar, rice and wheat straw, miscanthus, corn-stover bamboo, paper pulp or cotton, are currently used.

For reshaping an anti-solvent like water is added to the Ionic Liquid solution, triggering the reformation of cellulose’s hydrogen bonds.

Cellulose Reshaping specials

01

Ionic Liquids offer favorable physico-chemical properties

Ionic Liquids have negligible vapor pressures, being non-flammable and non-boiling, even at high temperatures. Ionic Liquids are ideal biomass-solvents due to their high gentle dissolution capacity, high recycling rates and low toxicity.

02

High molecular weights are retained

In contrast to other cellulose fiber producing processes, using Ionic Liquids as solvents results in remaining high molecular weight of the cellulose. This enables multi-recyclable cellulose filaments with higher stability.

03

Environmentally friendly processes

When using Ionic Liquids biopolymer dissolution, no addition of hazardous, flammable or odor-intensive chemicals (e.g. CS2) is necessary. The Ionic Liquid-based process also requires only a fraction of tquantities of water typically needed in such a process.

Water and Ionic Liquid are recycled and used for a new process cycle. Products from Ionic Liquid-based processes are free of harmful substances.

Key benefits

01

green production process

Ionic Liquids are used as direct solvents. No harmful additives are required. Only water and Ionic Liquids are needed and both can be recycled.

02

non-flammable

Due to absence of a boiling point and negligible vapor pressure Ionic Liquds are non-flammable.

03

non toxic

proionic’s standard Ionic Liquids solvents do not release any gaseous compounds into the atmosphere. Some proionic Ionic Liquids are already OEKO-TEX® ECO PASSPORT certified.

04

no ATEX

Ionic Liquids are non-flammable, resulting in safe and user-friendly production processes and lower investment cost for related equipment.

05

low side reactions

Cellulose in Ionic Liquids shows a low reactivity. No stabilizers or anti-oxidants are needed, contributing to even higher process-safety.

06

no fibrillation

Ionic Liquid-refined fibers are of very high lengths and do not fibrillate on their surfaces.

Main applications

01

Cellulose Filaments

02

Spherical Shapes

03

Surface Finishing

04

Chitin Filaments

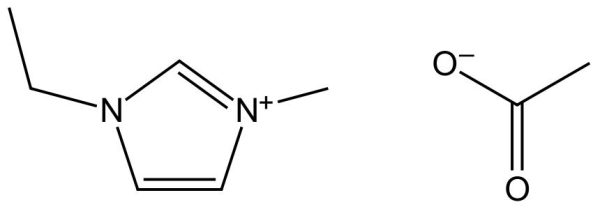

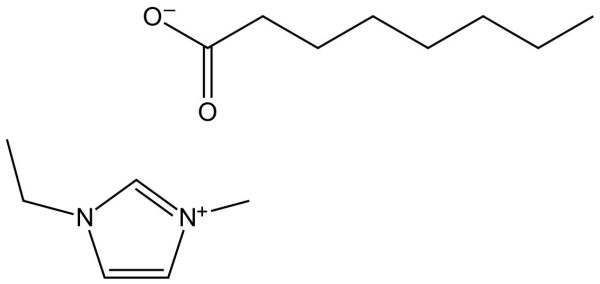

Proionic Ionic Liquids

Unmatched technologies for a more efficient, green and safe technical synthesis of Ionic Liquids.

Technological features - CBILS®

- Exclusive production technology

- Efficient production of ultra-pure ionic liquids

- Safe, halide- and waste-free production

- Scalable and ecological production processes

- More diversity by combining cations and anions in a modular system

- Applicable for all conventional liquids and any other tailor-made ionic liquids

Services

- Targeted development of application-optimized ionic liquids

- Development of new applications

- Process and process-engineering based expertise for targeted implementation of client requests

- Applied design of ionic liquids

- Tailor-made solutions according to your specifications

- All ranges from kg- to ton scale

- Bestseller ionic liquids in stock