Biomass Valorization

Combine economic value and positive impact on the environment

Ionic Liquids are recyclable

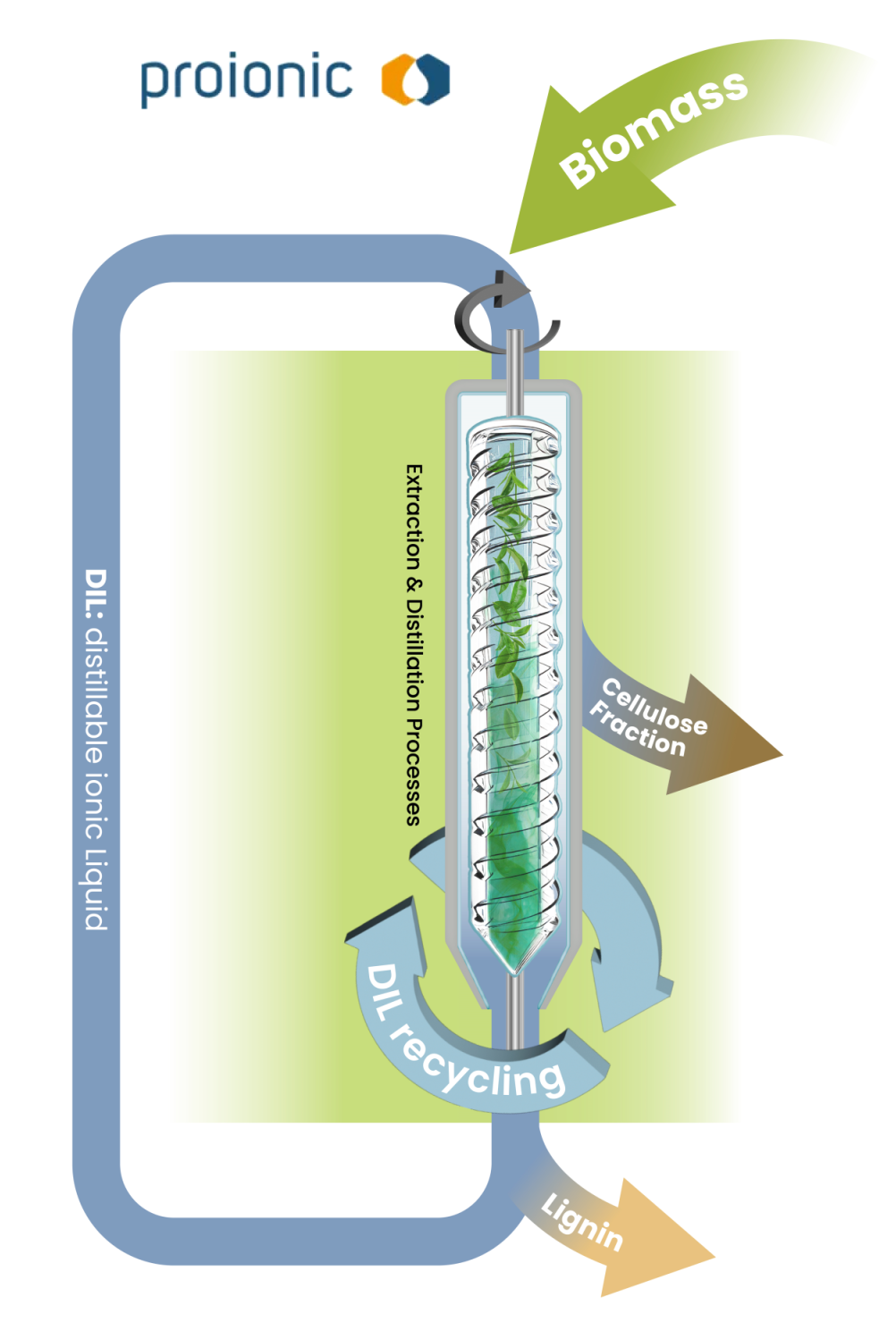

Distillable Ionic Liquids (DIL) are cheap and protic solvents capable of selectively dissolving Lignin from lignocellulosic matrices. The undissolved cellulosic fraction is separated and after washing and optional bleaching, can be converted to high-value products. The lignin is isolated by evaporation of the distillable ionic liquid (recycling rates >99%). The DIL is reused in the next extraction cycle.

Biomass Delignification using HIPE-REC® Technology

HIPE-REC® cellulose and lignin fractions offer a broad range of valorization options

Applications of proionic´s HIPE-REC® cellulose include textiles filaments, precursor fibers for carbon fibers, paper production, cellulosic microbeads, and biofuel production. Valorization of the lignin fraction coming from the HIPE-REC® process is under further development. The current offering targets on biofuels, carbon fibers, cosmetic additives, and foams.

Biomass Delignification using HIPE-REC® Technology

Once the biomass is fractionated into the polyaromate lignin and the polysaccharides hemicellulose and cellulose, a multitude of products are possible: They can be kept polymeric and used in diverse kinds of materials (link zu reshaping, fibers, paper, pulp, lignin). They can also be depolymerized into small molecules, which are further converted into bio-platform chemicals, biofuels and other bioproducts, replacing their fossil-based analogues. Lastely, they can open up completely new – e.g. biodegradable – pathways in chemistry, never seen in the fossil-based world so far.

Biomass Valorization specials

01

Outstanding product purity

Unlike the Kraft-process no sulphur-containing chemicals are involved in the HIPE-REC® process leading to sulphur-free Lignin. Due to optimized process parameters and the nature of the selected Distillable Ionic Liquids the structure of the produced Cellulose remains preserved (high degrees of polymerization).

02

Simple processing & low equipment cost

The two main process steps of the HIPE-REC® process, the selective extraction of Lignin and the recycling of the Distillable Ionic Liquids are optimized and can be performed using standard equipment applying moderate pressure and temperature conditions. This leads to lower equipment costs compared to other technologies such as the Organosolv process.

03

Recycling of Distillable Ionic Liquids

The invention of the HIPE-REC® patent family has created a new recycling approach for Distillable Ionic Liquids. Dedicated equipment assures the continuous formation of new surface during the distillation of Distillable Ionic Liquids from a viscous/solid matrix leading to recycling rates that have never been achieved before the invention of the HIPE-REC® process.

Key benefits

01

low process costs

02

simple process steps

The two main process steps can be performed in dedicated standard equipment applying moderate pressure and temperature conditions.

03

high purity of HIPE-REC® products

Cellulose and lignin produced through the HIPE-REC® process are of outstanding quality.

04

unmet DIL recycling rates

The Distillable Ionic Liquid used in the HIPE-REC® process can be recycled. Recycling rates can be greater than 99%.

05

various biomass sources

The biomass valorization process is applicable on a wide range of biomass waste sources.

06

process scale-up

Together with our partner GIG-Karasek we can offer the process scale-up to full prdocution level.

Main applications

01

Biofuels

02

Textiles & Fibers

03

Paper

04

Cellulosic Microbeads